Unlike low-end aluminum doors and windows used in other sunrooms and patio rooms, C-Thru’s Vinyl windows and doors utilize a welded construction. All of the headers and jambs are solidly welded into a strong one-piece frame. This one-piece welded vinyl frame will not come loose or separate like low-end aluminum windows and doors, which are made from four separate headers and jambs held together with screws.

In coastal applications, the salt in the air will corrode the hardware in your competitor's aluminum windows and doors, making the operation of aluminum doors and windows difficult over time. Our Omega windows and doors contain no such hardware, therefore they are perfect for coastal applications.

The superior insulation properties of Tuff-Core used in all C-Thru room walls means superior energy savings for you.

C-Thru’s unique vinyl composite patio rooms, with our welded vinyl construction, also have a much cleaner and refined look than aluminum rooms since they do not require near the amount of screws and hardware typically associated with typical aluminum construction. The cleaner look and higher efficiency of C-Thru’s vinyl sunrooms and patio rooms means that your client’s projects will look as good 10 years from now as the day they were built. That translates to better energy efficiency and a higher quality look now, and more resale value later.

Cardinal Insulating Glass with patented XL Edge Thermal Spacer

Insulating glass units supplied by C-Thru are manufactured in Cardinal IG’s highly automated state-of-the-art factory, and utilize Cardinal’s unique and patented XL Edge thermal steel spacer around the perimeter edge of the glass units. Since 1978 Cardinal has produced insulating glass units manufactured with a unique dual-seal system. This system uses a polyisobutylene (PIB) primary seal and a silicone secondary seal. PIB is the best material for keeping moisture out and argon in, and silicone is the ideal material to long-term structural integrity for the sealed glass unit. Units manufactured with this dual-seal system have demonstrated a failure rate of less than 1% after 20 years in the field. Based on decades of real-time experience in the field and in the brutal P1 lab test, where glass units are subjected to high temperature and humidity cycling while undergoing unusually high exposure to concentrated UV rays; PIB/Silicone dual-seal silicone systems last 4 to 10 times longer than other types of sealing systems insulating glass.

|

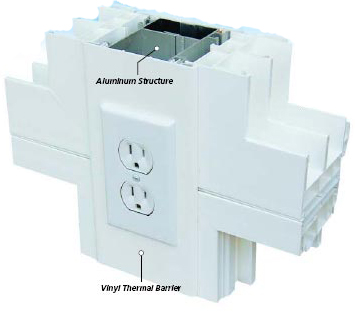

6063-T6 Aluminum posesses all of the characteristics required to build the high quality C-Thru Sunrooms. But a unique vinyl cladding system (called a thermalbarrier) placed on the inside and outside of each structural member eliminates the one negative attribute of aluminum - heat and cold transfer.

The Structural Thermal Barrier provides:

- 9 times more thermal value

- 7 times less likely to condensate

- Dramatically reduces the transfer of heat and cold while maintaining the great benefits of an aluminum structure

- Fewer exposed fasteners

|

Double Cam Window Lock

In these days of rising crime and home break-ins, security is a very important concern to your clients. At C-Thru we understand that, and have designed a locking system that takes a back seat to no one. , C-Thru uses a cam lock In our Omega product line Instead of latch-locks like our competitors use, which can become unlatched if the sliding panels of the windows are jarred by an intruder. Cam locks work better than any other type of locking mechanism because once the cam lock is engaged, it stays engaged. But C-Thru doesn’t stop there. Instead of using a single cam lock, C-Thru installs dual cam locks on it’s windows. Two locking mechanisms for double the security. Your clients might want to ask themselves a question … why aren’t other manufacturers as concerned about security as C-Thru? |